Attention all auto body shops and repairers and even consumers: it’s coming! Actually, you already knew it was coming, but now it is finally almost here! I’m talking about the all new, all aluminum Ford F-150. AutoBody-Review.com went to the SEMA show to get the inside scoop on what you need to know RIGHT NOW in order to be prepared if you intend to start fixing them, or if you plan to own one.

The auto body repair industry has a multitude of changing milestones, most of which represent the continual advancement of automotive design and construction. Ask any veteran body man about the most significant changes to their industry during their career, and I’m sure you’ll get a lot of similar responses. You’ll hear about Unibody Construction replacing full body-on-frame construction. You’ll hear about the MIG welder replacing gas welding, and about plastic filler replacing lead fillers, air bags, hybrids and Ultra high strength steel. One day, today’s body man will tell the future generation about the major milestone that is currently being led by Ford Motor Company. We will all remember when cars and trucks switched from steel to aluminum.

For the Consumer, the F-150 Will Be a "Game Changer"

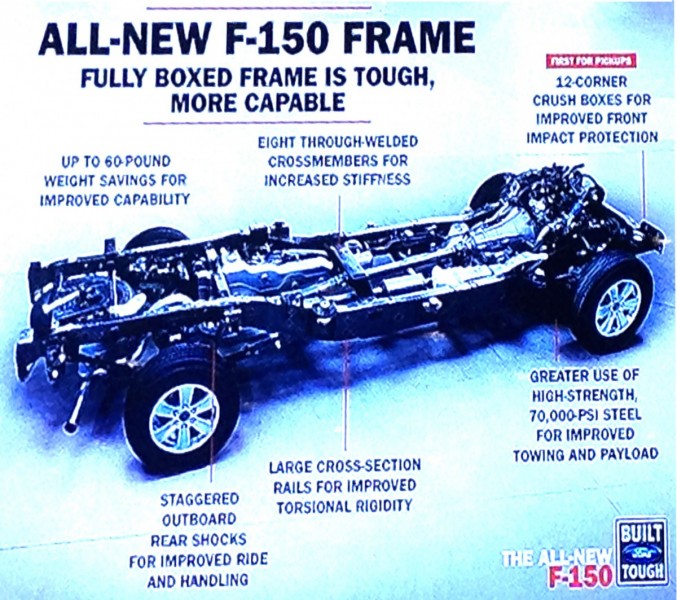

It is Tougher. The new 2015 F-150 has an all-new, high-strength steel frame, with a high-strength aluminum-alloy body, and more than 10-million miles of testing. In essence, Ford is “reinventing ‘Built Ford Tough’”.

It is Smarter. There are about 11 new class-exclusive features. With these features, you’ll find the F-150 has a 360-degree camera view, which will help the driver to park, or off-road with more efficiency. There are also lights inside the pickup bed, including a step ladder. All lights (headlights, taillights, side mirrors) are LED, and possibly the coolest thing is the remote tailgate release.

It is Far More Capable. With the conversion from steel to “high strength military grade aluminum alloy” body, this gives the consumer a night and day difference from any previous F-150. For instance, the truck is up to 700 pounds lighter in weight than previous models. This will greatly affect fuel economy, making driving the new F-150 more affordable, and allow the driver to tow and haul more.

For the Auto Body Shops, There Will Need to be Some Changes

The F-150 isn’t the first vehicle to incorporate aluminum in its construction, but it is the first to use it for nearly the entire vehicle. With this new milestone, you can guarantee that in the very near future, more and more cars will be made almost entirely with aluminum. So, if you have previously skirted the aluminum cars and sent them to specialist for repair because you couldn't justify the investment in aluminum repair technology, let me explain what has to be changed if you want to continue to stay in business in the very near future.

As I mentioned before, the F-150’s body is made of aluminum. Now, I’m not talking about just a panel here and there. Nearly the whole thing is aluminum. While the aluminum repair process is similar to steel repair, there are still various methods and tools that must be implemented in order to repair the vehicle correctly. For instance, it is required to have equipment that captures and stores any aluminum dust that may come during repair. The reason this is important is because aluminum is hazardous, due its ability to explode. There are places like Eurovac that sells these required repair equipment at SEMA. Stop by booth #11246 in North Hall to learn more!

Also, aluminum and steel can cross contaminate each other, which causes rapid corrosion issues, and will blister and peel the paint. Ford ran into this problem in the manufacturing side when the 2007-2009 Ford Mustang aluminum hood started having paint problems.

Aluminum repairs also require rivet bonding, instead of welding on structural repairs. You can completely forget about using any welding in the F-150’s aluminum braces, supports or replacement A B C, and door hinge pillars. You will also need to buy a self-piercing rivet gun. Currently, Henrob and Pro Spot are the only approved guns.

There are many more requirements and necessities the auto body industry will have to implement in order to properly repair the F-150, including your shop's facility. To be a certified repairer of the new F-150, and all the cars that will soon follow, you will need a dedicated aluminum area, or at a minimum, and approved work area separation system with curtain walls or with prep stations that also provide dust extraction.

Major Investment in Training of Your Staff

If you are a repair facility that is unsure if you are yet equipped and trained to properly repair the new F-150, then you may want to consider attending either an I-CAR training course, or go online. You can find an online training course outline via motorcraftservice.com.

The aluminum-capable program offered through Ford’s Rotunda equipment division includes training and welding certification from I-CAR and a list of required equipment. For shops starting from scratch for aluminum, the tools and equipment require an investment of between $30,000 and $50,000, and until April 30, Rotunda is offering Ford dealers a 20-percent discount on qualifying purchases.

The Future is Here

Where were you when cars switched to aluminum? Hopefully you were ready for the change, got ahead of the game, and were able to make it one of the most profitable things you ever did for your shop.

While out at the SEMA show, make sure you make contact with all these vendors so that you can begin to convert your shop to a modern aluminum repair facility.